Developing Guayule Resin Adhesives

Guayule resin is a major by-product of the guayule rubber extraction process; therefore, utilization of the resin is an important factor for the overall economic sustainability of guayule rubber production. SBAR research is looking at the characteristics of the guayule resin to identify high value-added applications.

Guayule resin has a naturally weak adhesion force that indicates a tendency for guayule resin to be useful as an adhesive. Development of guayule resin as a bio-based adhesive for wood products is underway. Current research is focused on guayule resin characteristics, improvement of physiochemical properties, and enhancing guayule resin adhesion strength.

Formaldehyde-based adhesives occupy the majority of the market share due to strong adhesion. However, the high marketability of healthy and environmentally friendly products shows an opportunity for guayule resin as bio-based adhesives for wood products.

The success of this research not only fulfills the economic sustainability of guayule rubber production but also delivers sustainable guayule resin adhesives that are safe for humans and the environment, and helps to reduce the reliance on petroleum-based products.

Raw form of guayule resin

Research Leads

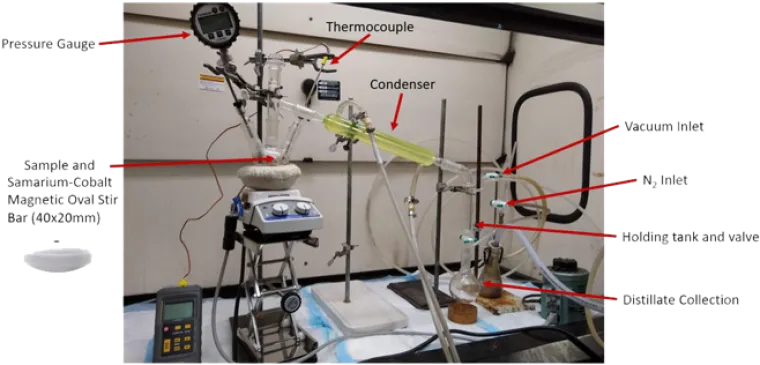

Vacuum Distillation of Guayule Resin with Models

Guayule resin is a viscous, water insoluble mixture of primarily terpenoid and phenolic secondary compounds and currently has little practical use in its raw form. Separating it into its various components via vacuum distillation is a promising method to create chemical mixtures that would better serve as foundations for other products.

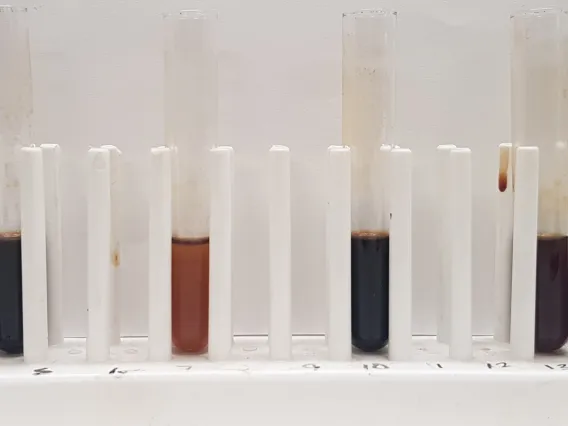

Secondary compounds distilled from guayule resin

Since most of these compounds are nonvolatile, a vacuum is needed to reduce the high-boiling points while keeping the temperature low to avoid molecular breakdown. Adhesives, pesticides, and paint/coatings are the most likely end uses of the resin co-product.

Vacuum distillation experiments are done using both a single-stage and fractionating column distillation setup.

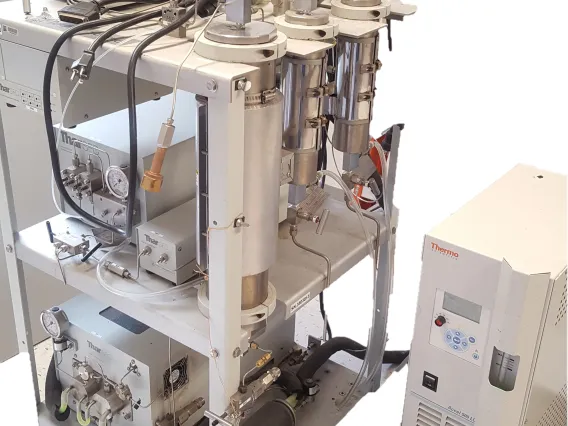

Vacuum distillation setup in the laboratory

A small amount of solventless resin is heated under constant pressure or held at a desired temperature while the pressure is reduced from atmosphere. Inert nitrogen gas controls the pressure to prevent side reactions. Collected fractions are analyzed for purity and composition, and the resulting data will be used to model a distillation column.

Research Leads

Bioassays for Insect Repellency

The non-rubber extracts (resin) of guayule contain potential high-value secondary compounds (sesquiterpene esters, triterpenoids, sterols, and triacyclglycerols) with applications in anti-inflammatory drugs, coatings and adhesives, termite resistance, antifungal and antimicrobial materials, resin multipolymers, and insecticides.

Due to the adverse effects of long-term application of synthetic insecticides on human health and ecosystems, bio-based, non-toxic insecticides show promise. SBAR researchers’ characterization of guayule resin showed the presence of mono- and sesquiterpenes, and their oxygenated derivatives (like α- and β- pinene, D- limonene, β-phellandrene, elemene, β-eudesmol). These compounds are among the active ingredients for currently used insect repellents. Triterpenoids (like argentatins) are another group of compounds in guayule resin that have potential repellent activity.

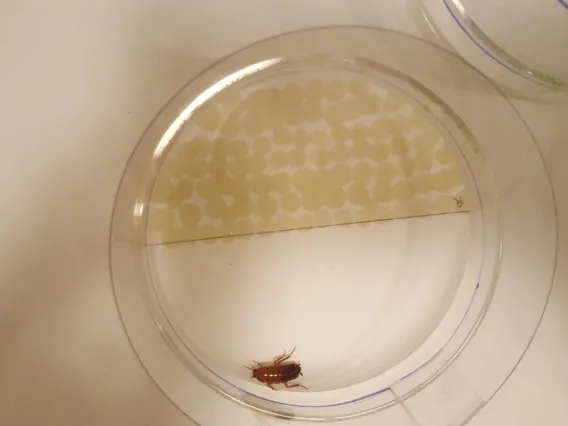

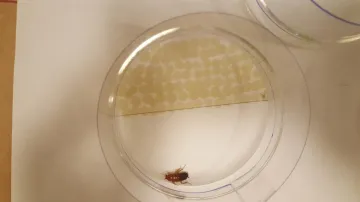

Current work includes testing the toxicity and avoidance efficacy of guayule resin fractions as repellents for urban pest insects like German cockroaches (Blatella germanica) and Turkestan cockroaches (Blatta laterali), as well as reference models. Future work will evaluate guayule resin’s repellency of bed bugs (Cimex lectularius), which have shown a recent resurgence in North America.

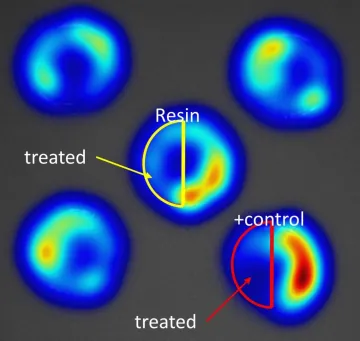

“Heat maps” showing movement of individual cockroaches over a 10-min period in an untreated area

Half-treatment area for testing repellency of guayule resin on a Turkestan cockroach

Research Leads

Separation of Guayule Resin

The separation, fractionation, and purification of guayule resin are critical to any value-added use of the complex mixture. Supercritical CO2 extraction is one potential method for separation. The extraction is significantly faster and better controlled than conventional liquid solvent extraction. Parameters that affect the extraction yield and selectivity are pressure, temperature, co-solvent ratio, and time.

Dry biomass is placed in an extraction vessel and pressurized with CO2 to dissolve the target compounds. By manipulating the temperature and pressure of the fluid, different groups of compounds can be solubilized and selectively extracted.

Research Leads

The Waters SFE-2000F2-1-C50 extraction system consists of a 2 L extraction vessel, two 500 mL fraction collecting vessels, an automatic back pressure regulator, two manual back pressure regulators, a heat exchanger, P-50 high pressure CO2-solvent pump, a P-200A high pressure CO2 pump, a temperature controller, and a chiller.

Biochemical Characterization of Guayule Bagasse

Bagasse refers to the residues from a product extraction from plant biomass, traditionally the fibrous material left over after the extraction of sugar from sugarcane. For guayule, the bagasse consists of the woody stem material left after resin and rubber extraction at the processing facility. For guar, bagasse consists of the plant stem, leaf, and bean pod material left on the field after combine harvesting. Bagasse has several potential applications: direct use as a solid fuel (i.e. guayule bagasse pressed into pellets for combustion in pellet stoves for heat), conversion to a liquid fuel through biochemical or thermochemical methods, return to the soil as soil cover/conditioner for nutrients and organic matter, incorporation into composite materials as a fibrous filler, etc. The characteristics and available amounts of each bagasse provides information about which application will be the most sustainable.

Characterization consists of several measurements to describe bagasse composition and properties: biochemical content by National Renewable Energy Laboratory methods for moisture, ash, extractives, hemicellulose and cellulose; elemental content by CHNS combustion and by acid digestion/inductively coupled plasma optical emission spectroscopy (ICP-OES); energy content by higher heating value analysis by bomb calorimeter, particle size distribution by sieving, and bulk density.

Research Leads

Metabolic Biomarkers in Cold- and Freezing-resistant Guayule

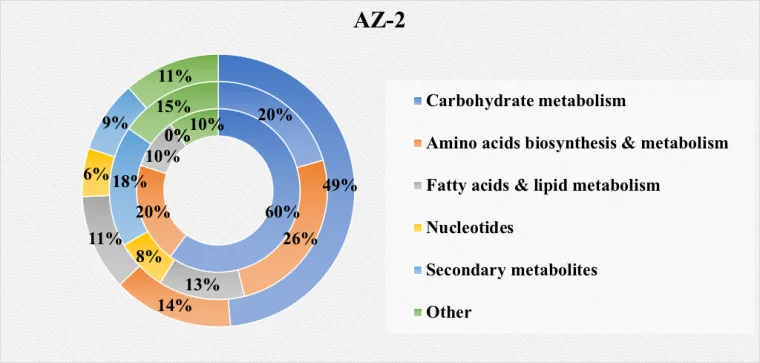

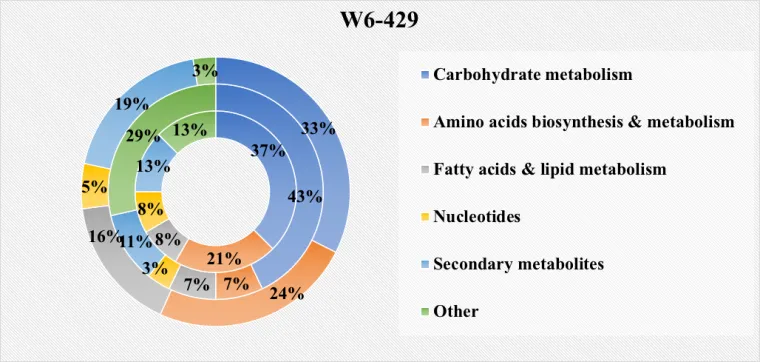

SBAR researchers are collaborating to conduct metabolome analyses on guayule. A recently completed study analyzed the metabolome of guayule leaves of the germplasms AZ-2 and W6-429 exposed to cold-acclimation and freezing temperatures. SBAR researchers used guayule metabolomes to identify metabolic biomarkers for cold-acclimation and freezing. (Publication in press.)

Classification and percent biomarkers from guayule AZ-2.

Classification and percent biomarkers from guayule W6-429.

Classification and percent of metabolic biomarkers from guayule AZ-2 and W6-429 respond to both cold-acclimation and freezing temperatures, freezing temperatures, and cold-acclimation (outer, middle, and inner circles) into six categories. The colors on the donut graphics represent the six functional categories on which the metabolic biomarkers were grouped and their total percentage within the plant.

A follow-up study on guayule temperature response in leaf and bark tissues is underway to gather information on the possible sequence of events leading to rubber biosynthesis and accumulation within the plant. Three germplasm groups with mature plants in the field that have low rates of cold injury are being studied for their metabolic and transcriptomic response to decreasing temperature. Initial samples were collected in September 2020, and subsequent monthly samples will be collected through March 2021.

Guayule germplasms with low cold injury in Las Cruces, NM.

Research Leads

Mass Spectral Characterization of Guayule Resin Compounds

During rubber production, two residue streams are generated: a dry, woody bagasse and a complex, resin-rich liquid, which provide a potential pool of value-added products.

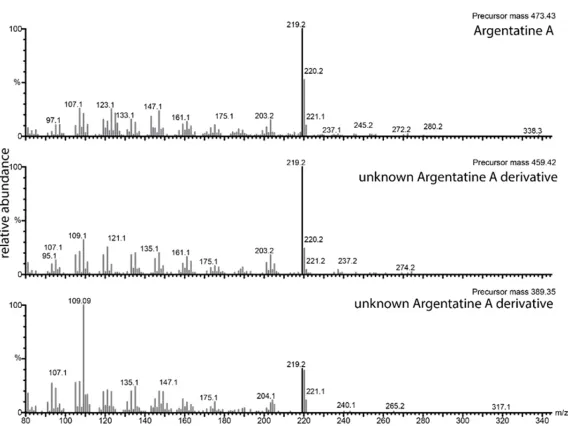

A multidisciplinary SBAR team of researchers are working to unlock the chemical identity of the thousands of compounds within guayule resin using advanced mass spectrometry techniques such as Fourier transform ion cyclotron resonance (FT-ICR) mass spectrometry. The results are also used to inform other (lower resolution) mass spectrometry techniques that can help estimate the quantities of the compounds within the resin.

FT-ICR MS is not only being applied to determine valuable compounds in guayule resin, such as argentatins, guayulins, and fatty acids, but also in a “petroleomics” approach to help correlate the molecular-level composition of biocrude oils generated from the hydrothermal liquefaction of guayule bagasse to the biocrude oil properties and behaviors during refinement into usable fuels.

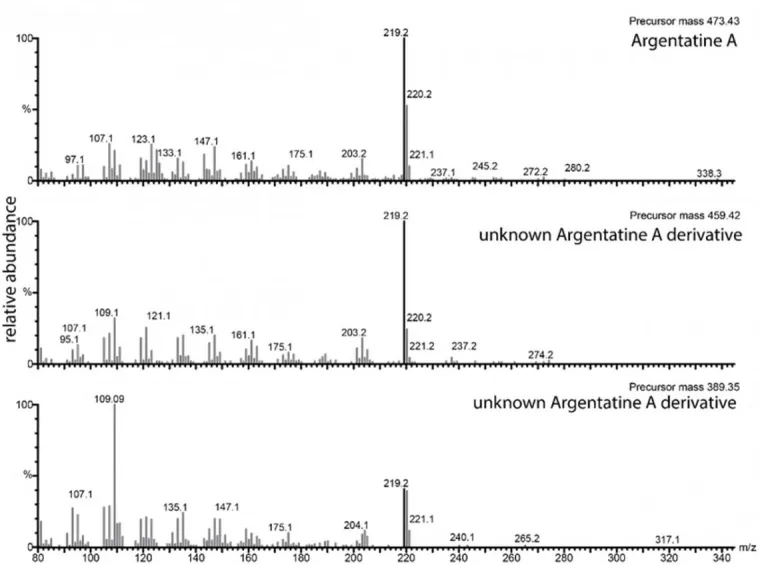

MSMS spectra for Argentatin A and its derivatives.

Research Leads

Synthetic Biology and Biocatalytic Conversion of Guayule Resin Metabolites

Guayule resin contains a complex mixture of terpenoid and phenolic secondary metabolites. Some of these metabolites show interesting bioactivities, and may be developed as antimicrobials, insect repellents, or anticancer substances. Other metabolites may serve as high value starting materials for the fine chemical industries.

Filamentous fungal cultures growing and sporulating on agar media.

Understanding the biosynthetic pathways that yield these metabolites could provide SBAR researchers with targets for guayule germplasm improvement – increasing the production of desired metabolites, or eliminating or reducing the production of unwanted compounds. Using bioinformatic methods such as comparative genomics and transcriptomics, together with retrobiosynthetic analyses and comprehensive literature searches, SBAR researchers generate biosynthetic hypotheses for the major guayule metabolites. These hypotheses are then confirmed using synthetic biology: heterologous expression of key biosynthetic genes in a yeast host and identifying the produced biosynthetic intermediates.

Naturally occurring guayule secondary metabolites are also providing starting points for structure diversification and optimization. Biocatalysis is a sustainable, environmentally friendly and scalable method to modify the structures of complex molecules. During biocatalysis, SBAR researchers use cultures of filamentous fungi, bacteria, or recombinant yeasts expressing secondary metabolite biosynthetic enzymes. These cultures are supplemented with a purified starting compound, such as terpenoids or their intermediates from guayule resin. Novel, modified metabolites are detected by various analytical techniques, the altered compounds are purified, and their structures determined. Novel compounds are then tested for their various biological activities in antimicrobial, anticancer and insect repellency assays.

Biocatalytic transformation of guayule metabolites with submerged (shake flask) fungal cultures.